(Built-in couplings) High-Pressure Cement Hose SNG-SZ NSG-SZ

• application:

• it is used in well cementation system of offshe l drilling rig, flexible connection between cementing pump top drive f delivery of high-pressure cement.

• stard: api spec 7k / iso 6807 / gb/t 24145

• api monogram no.: 7k-0458

• hose structure:

tube: cr rubber based liner sealing layer, abrasive resistance, alky-acid resistance, high temperature resistance.

breaker layers external protection layers: high tension textile fabric

maj reinfcement f withsting pressure: high strength steel cable

cover: neoprene based cover rubber, anti-flaming, wear resistance, oil resistance, ozone & ageing resistance, uv resistance, which is applicable f marine environment.

• fire proof grade:

regular supplied hoses meet fire proof grade sr6a, 704℃ ×5min

fire-rated hoses supplied as per request with extra fiberglass out layers f fire shield, meet

fire proof grade sr6b, 704℃ ×30min

• embedded electric heat trace cable is available as request f low temperature operating condition.

• different option of external protection layer are available as request by our recommendation accding to specific operation condition, f example stainless steel arm outer wrap, embedded stainless steel wire in cover, polyethylene spiral guard, etc.

• wking temperature range: class ⅱ , -25 to +100 ℃

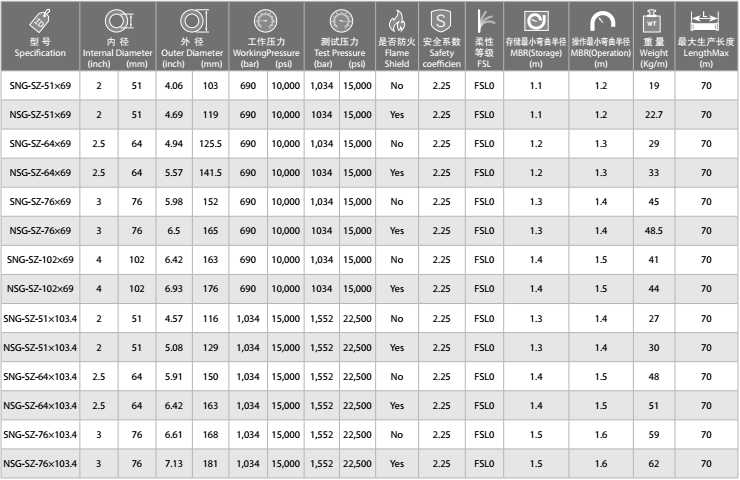

• flexibility specification level: fsl0

• maximum continuous length: 70m

• length tolerance: length up to 6.4m, with tolerance ± 64 mm; length longer than 6.4m with tolerance ± 1%

• measurement basis of minimum bending radius (mbr) is center line of each hose

+86-535-2615988

+86-535-2615988 Contact us

Contact us• application:

• it is used in well cementation system of offshe l drilling rig, flexible connection between cementing pump top drive f delivery of high-pressure cement.

• stard: api spec 7k / iso 6807 / gb/t 24145

• api monogram no.: 7k-0458

• hose structure:

tube: cr rubber based liner sealing layer, abrasive resistance, alky-acid resistance, high temperature resistance.

breaker layers external protection layers: high tension textile fabric

maj reinfcement f withsting pressure: high strength steel cable

cover: neoprene based cover rubber, anti-flaming, wear resistance, oil resistance, ozone & ageing resistance, uv resistance, which is applicable f marine environment.

• fire proof grade:

regular supplied hoses meet fire proof grade sr6a, 704℃ ×5min

fire-rated hoses supplied as per request with extra fiberglass out layers f fire shield, meet

fire proof grade sr6b, 704℃ ×30min

• embedded electric heat trace cable is available as request f low temperature operating condition.

• different option of external protection layer are available as request by our recommendation accding to specific operation condition, f example stainless steel arm outer wrap, embedded stainless steel wire in cover, polyethylene spiral guard, etc.

• wking temperature range: class ⅱ , -25 to +100 ℃

• flexibility specification level: fsl0

• maximum continuous length: 70m

• length tolerance: length up to 6.4m, with tolerance ± 64 mm; length longer than 6.4m with tolerance ± 1%

• measurement basis of minimum bending radius (mbr) is center line of each hose

Hydro Decoking Hose

Hydro Decoking Hose (Built-in couplings) High-Pressure Cement Hose

(Built-in couplings) High-Pressure Cement Hose Fire-Rated Tensioner Hose

Fire-Rated Tensioner Hose Flexible Choke & Kill Hose

Flexible Choke & Kill Hose Flow Line Hose (Inner Wall Armored For Gas Service)

Flow Line Hose (Inner Wall Armored For Gas Service) (Built-in couplings) High-Pressure Mud Hose/ Rotary Hose/ Vibrator Hose

(Built-in couplings) High-Pressure Mud Hose/ Rotary Hose/ Vibrator Hose (Swaged couplings) High-Pressure Mud Hose/ Rotary Drilling Hose/ Vibrator Hose/ Cement Hose

(Swaged couplings) High-Pressure Mud Hose/ Rotary Drilling Hose/ Vibrator Hose/ Cement Hose (Built-in Couplings) Unbalanced Drilling Hose

(Built-in Couplings) Unbalanced Drilling Hose Flexible Choke & Kill Hose

Flexible Choke & Kill Hose Jetting Hose

Jetting Hose Hydro Decoking Hose

Hydro Decoking Hose Fire-Rated Tensioner Hose

Fire-Rated Tensioner Hose Flexible Choke & Kill Hose

Flexible Choke & Kill Hose Flow Line Hose (Inner Wall Armored For Gas Service)

Flow Line Hose (Inner Wall Armored For Gas Service) (Built-in couplings) High-Pressure Mud Hose/ Rotary Hose/ Vibrator Hose

(Built-in couplings) High-Pressure Mud Hose/ Rotary Hose/ Vibrator Hose (Swaged couplings) High-Pressure Mud Hose/ Rotary Drilling Hose/ Vibrator Hose/ Cement Hose

(Swaged couplings) High-Pressure Mud Hose/ Rotary Drilling Hose/ Vibrator Hose/ Cement Hose (Built-in Couplings) Unbalanced Drilling Hose

(Built-in Couplings) Unbalanced Drilling Hose Flexible Choke & Kill Hose

Flexible Choke & Kill Hose Jetting Hose

Jetting Hose

Copyright©2019 SHANDONG YUELONG RUBBER&PLASTIC TECHNOLOGY CO.,LTD. All Rights Reserved.

Copyright©2019 SHANDONG YUELONG RUBBER&PLASTIC TECHNOLOGY CO.,LTD. All Rights Reserved.